Frequency independent pulse shaping with magnetically levitated choppers

The trend in experiment requirements is increasingly moving towards shorter pulses at lower frequencies. How we have been able to make a step in this direction and can support your research.

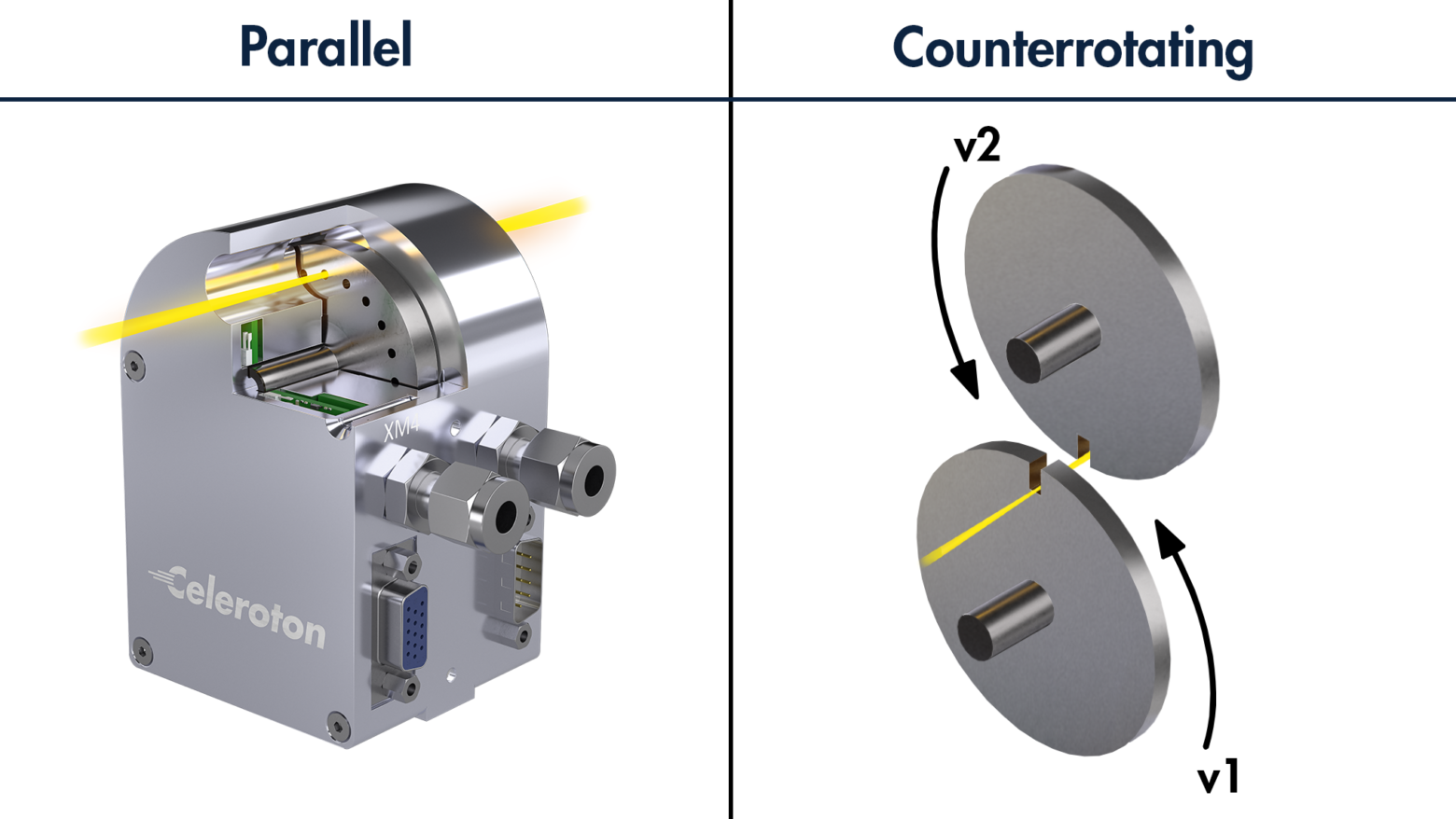

We are seeing a trend in experiment requirements, alongside with the current and future beamline upgrades, requiring shorter pulses at relatively moderate frequencies. These requirements combined are hard to achieve with a state-of-the-art simple parallel topology design of the chopper, where a single disc is operated with its rotating axis parallel to the beam (see Figure 1 “Parallel”) because with this topology the ratio between pulse shape (circumferential speed) and frequency (rotational speed) can only be influenced by the disc diameter. With the parallel topology design, the requested requirements would therefore result in a very large disc. Due to the material strength limitations, this would technically not be feasible and result in limitations regarding control dynamics and positioning issues within the end station of the experiment.

In order to meet the requirements and still be able to use our trusted small-scale chopper technology, we came up with the counterrotating topology design approach where two choppers with parallel topology are arranged in series with opposite direction of rotation (see Figure 1 “Counterrotating”).

Figure 1: Parallel vs. counterrotating topology design

The counterrotating topology has the advantages that the two counterrotating slots will reduce the opening and closing time by a factor of two. This allows the realization of even shorter pulse shapes. Further the frequency can be influenced by changing the rotational speed of the second chopper (v2) compared to the first one (v1). If the first chopper rotates n turns within a given time and the second chopper rotates n+1 turns in the same time, only every nth pulse is passing the two choppers. With that, the frequency can be reduced without the need of a third chopper disc in series.

With the counterrotating approach, a pulse shape with an opening and closing time of below 40ns and a frequency in the range of 1 kHz can be achieved. To learn more about our choppers and how they can benefit your research, contact us via moc.notorelec@ofni or +41 44 250 52 20 so we can determine the technical feasibility of your specifications.

For more information, read our white paper on the topic.