Turbocharging satellite cooling for high speed communication

The challenges of cooling in space and how Celeroton’s oil-free turbo technology overcomes them.

The challenges of cooling in space and how Celeroton’s oil-free turbo technology overcomes them.

In our increasingly connected world, robust and high-performance communication infrastructure is becoming more important. As data traffic increases, satellites are not only growing in number, they also carry more powerful communication equipment. But more power also means more heat that needs to be removed.

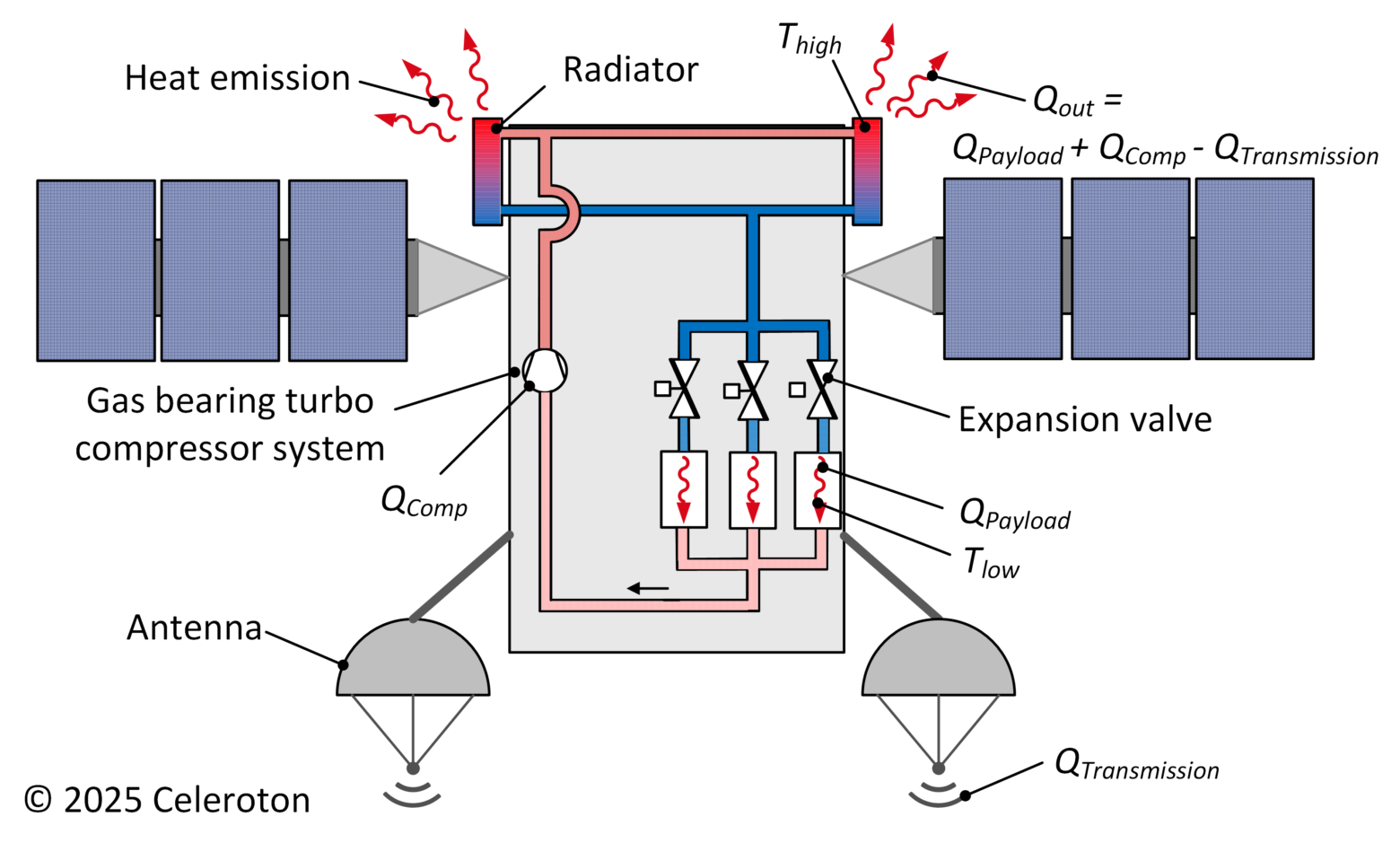

While space may seem freezing cold, the lack of an atmosphere means satellites cannot use convection to get rid of waste heat. Instead, Satellites rely entirely on thermal radiation to dissipate excess heat. How much heat is radiated is proportional to the surface and proportional to the 4th power of the temperature. Increasing the surface means larger radiators and therefore heavier and bulkier satellites, or deployable radiators increasing the surface by complex mechanisms. Alternatively, the radiated power can be drastically increased, if the waste heat is rejected at a higher temperature.

This is exactly where a heat pump makes a difference. By lifting waste heat to a higher temperature level, it allows smaller radiators to reject the same amount of excess heat – enabling the usage of precious volume and surface of satellites for payload such as communication electronics and antennas.

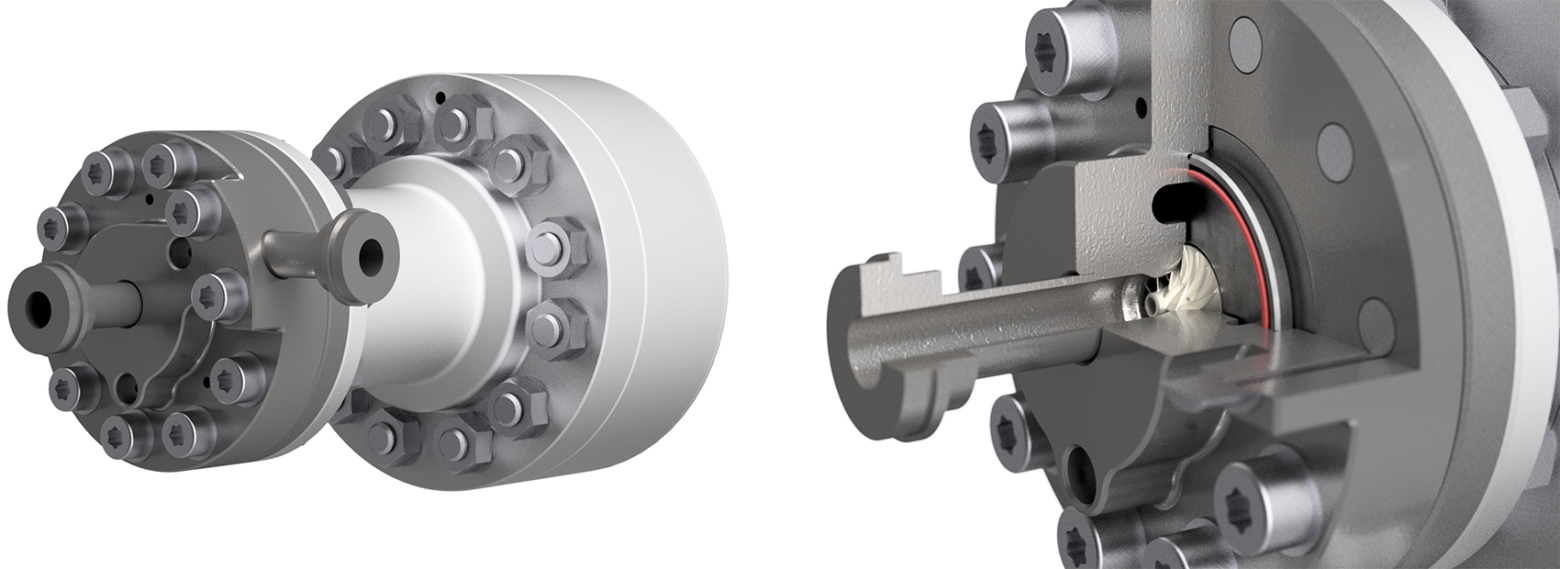

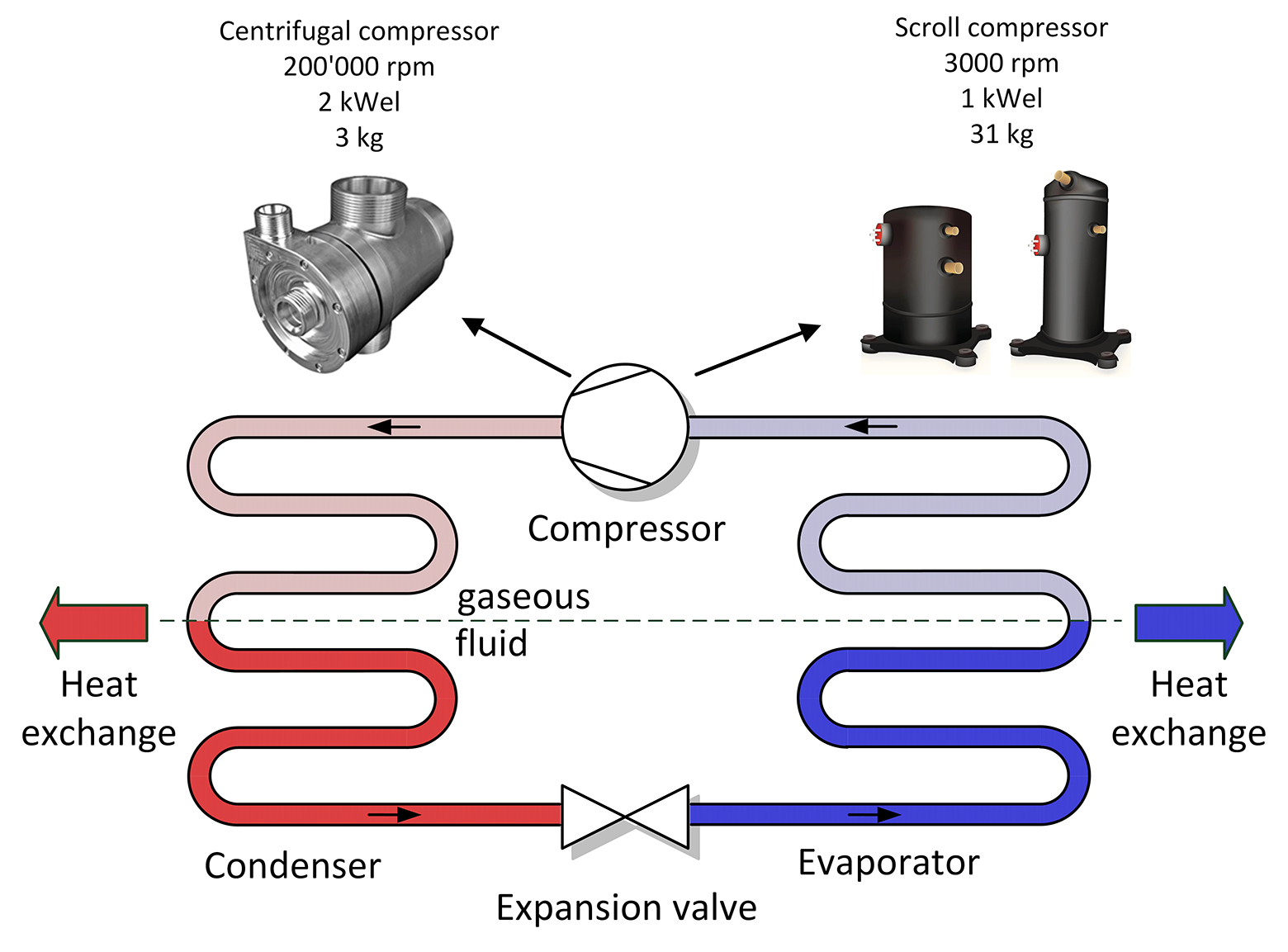

Contracted by ESA, and together with a consortium of companies we are developing a heat pump system for satellite cooling with ammonia as the refrigerant. The core component of this heat pump system is a turbo compressor, also called centrifugal compressor, based on Celeroton’s gas bearing technology. Now we are assembling a first compressor which then will be tested thoroughly to verify the concept. To support this effort, we designed and assembled a new, dedicated test bench. The test bench is tailored for the operating conditions at elevated pressures and temperatures to test the compressor under realistic conditions.

You may wonder why gas bearing turbo compressors are ideal for space applications. There are several good reasons:

The project aims to explore the possibilities and put ambitious efficiency targets to test, including quantifying the benefits of this technology over regular systems in terms of mass, volume, micro vibration emission and energy consumption – the four most critical resources in orbit.

Celeroton’s turbo compressor for heat pumps represents a promising path forward in advanced thermal management for next-generation satellites – low in vibration, compact, clean, and built for performance in one of the harshest environments we know: space. As this example shows: Celeroton drives future technologies which not only boost the efficiencies in established processes but also enable solutions not feasible with the current state of the art.

If you have questions or inquiries regarding your own project contact us via +41 44 250 52 20 or moc.notorelec@ofni.