In advanced life-support and in-situ resource utilization systems, reliable and contamination-free gas compression is essential. Two examples are four bed carbon dioxide scrubbers (4-bed CO₂ scrubbers) and solid oxide electrolysis cells (SOEC).

Four bed CO₂ scrubbers are used in artificial habitats, such as spacecraft, to continuously remove carbon dioxide from the breathing air. By cycling through four adsorbent beds in sequence, they ensure a continuous supply of purified air for crew members, while regenerating the beds for reuse. This process requires a compressor that can deliver a steady flow of air or process gas at defined pressures — without introducing contaminants or requiring frequent maintenance.

In solid oxide CO-electrolysis space applications, efficient gas handling plays a crucial role. In this process, steam (H₂O) and CO₂ are converted into a synthesis gas (syngas) mixture of hydrogen (H₂) and carbon monoxide (CO) at the cathode, while oxygen (O₂) is generated at the anode. The produced CO can either be vented, stored, or further converted — for example into methane or liquid fuels via Fischer-Tropsch synthesis — depending on the mission duration and resource utilization plan. Reliable compression of the process gases is vital for maintaining system efficiency and ensuring stable operation under varying environmental conditions.

Celeroton’s gas-bearing turbo compressors are ideally suited for these demanding applications. They are:

- Contact- and oil-free: zero contamination

- Compact and lightweight: minimizing system footprint and mass

- Magnetic or gas bearings: vibration- and maintenance-free

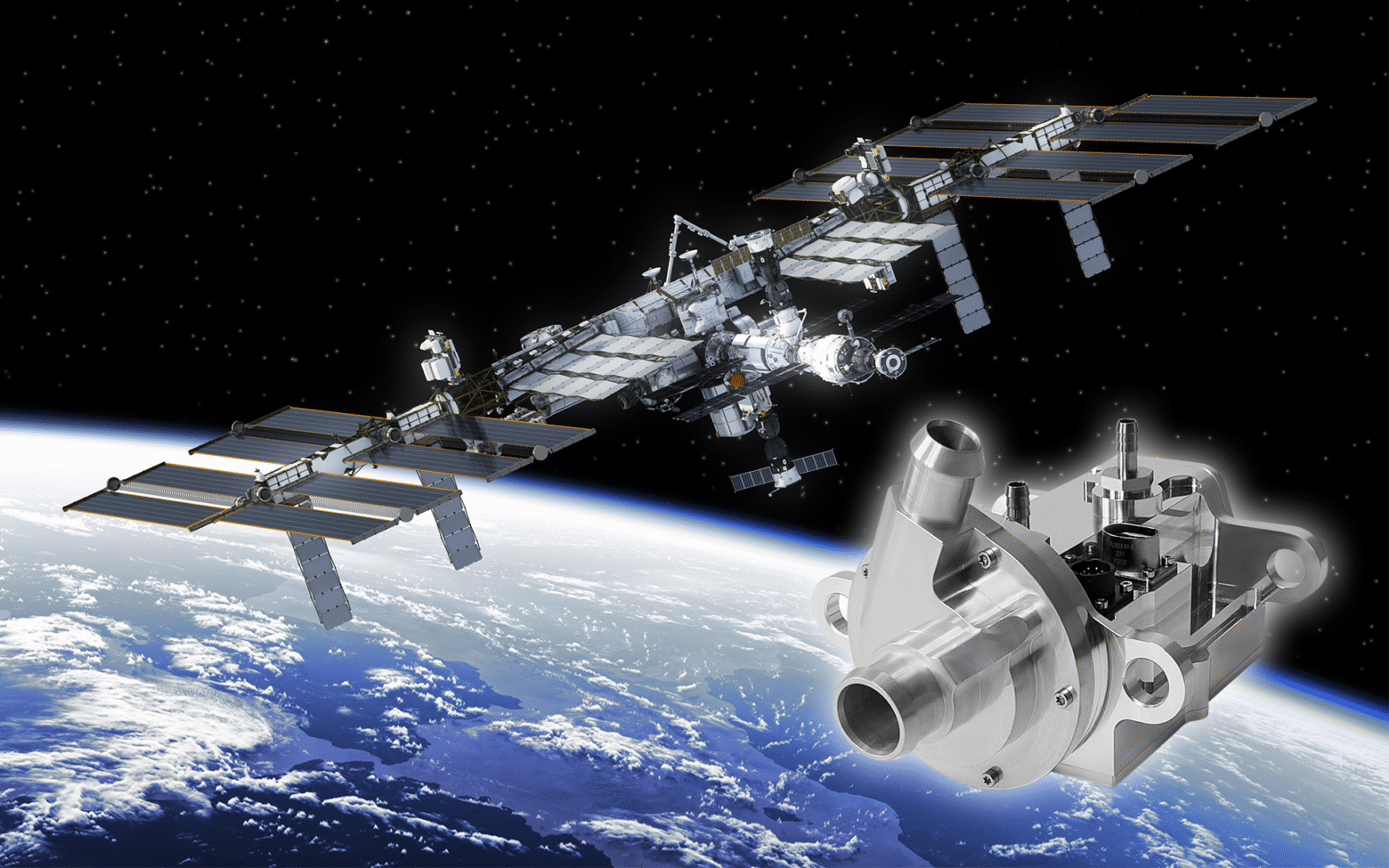

Whether as a commercial-off-the-shelf (COTS) solution or tailored to mission-specific requirements — such as optimized aerodynamic stages and/or suction gas-cooled motors — Celeroton turbo compressors, combined with Celeroton’s matching high-speed power electronics, offer a complete and efficient solution for gas compression and blower needs in space and other critical environments.

From maintaining breathable atmospheres or enabling resource conversion under in space stations or in lunar or marsial habitats, Celeroton’s technology delivers the performance, reliability, and cleanliness needed for the future of human space exploration.