Turbolent flow

Turbulent calculation models for gas bearings enable compressors to operate at high inlet pressures

Turbulent calculation models for gas bearings enable compressors to operate at high inlet pressures

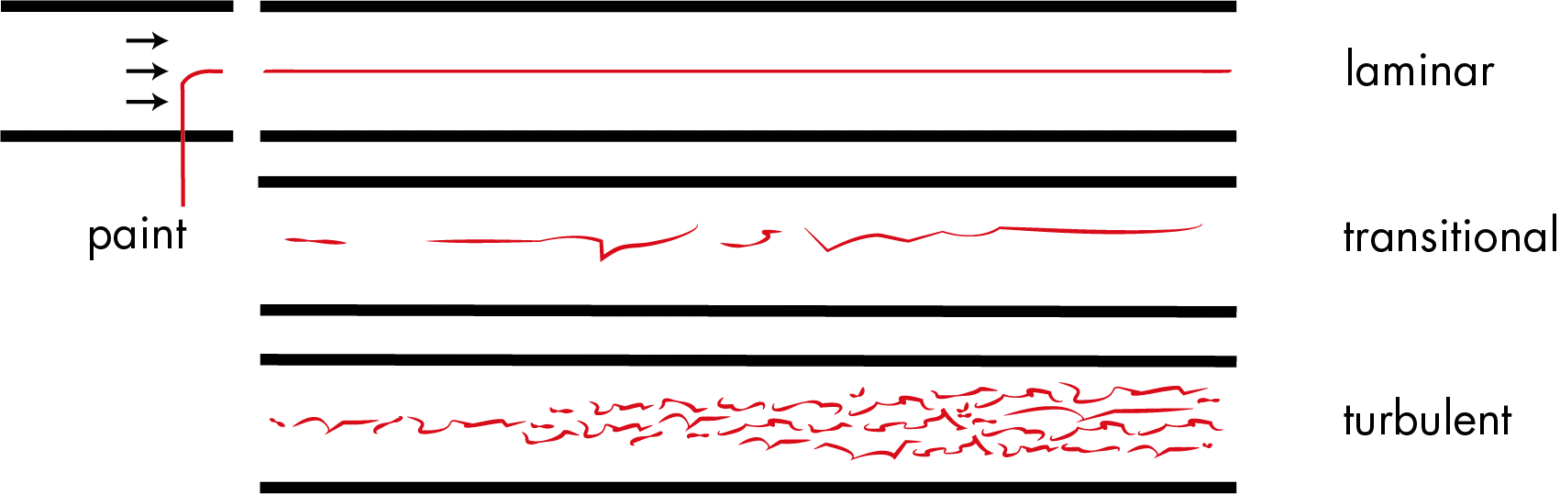

The new generation of high-pressure compressors from Celeroton CT-6000-Ar can operate at inlet pressures of up to 190 bara. With these specifications, not only mechanical aspects must be considered in the system design, but there are also special constraints for the design of the gas bearings. Due to the high density, the flow pattern in the bearings changes from laminar to turbulent flow. The figure below illustrates this using Reynolds’ well-known streamline experiment from 18831. Here, paint is introduced into a pipe flow of variable velocity (and thus Reynolds number). At low speeds, the paint remains a straight line. If the Reynolds number exceeds a critical value, increased cross-flow exchange occurs in the flow – the streamline becomes turbulent.

Previous literature approaches to calculating the herringbone gas bearing structure only model the laminar region2. This was sufficient until now, as common applications have a low Reynolds number due to the relatively narrow bearing gap and process boundary conditions, and thus have a laminar flow profile. However, the high gas density combined with other gas properties leads us into the turbulent flow range for the CT-6000-Ar. The calculation and modeling effort increase significantly here, as is known from various publications in the field of numerical flow simulation of radial compressors. With Celeroton’s development experience, simplified calculation models have been developed and validated, which now also enable the design of herringbone gas bearing structures in the turbulent flow range. This opens up new application prospects for gas-bearing turbo compressors at high pressures or even for gases with very high densities, such as refrigerants.

[1] Reynolds, Osborne: An Experimental Investigation of the Circumstances Which Determine Whether the Motion of Water Shall Be Direct or Sinuous, and of the Law of Resistance in Parallel Channels, Vol. 174, Philosophical Transactions of the Royal Society of London, 1883, pp. 935-982.

[2] Vohr, J. H., and Chow, C. Y., Characteristics of Herringbone-Grooved, Gas-Lubricated Journal Bearings, 87(3), Journal of Basic Engineering, 1965, p. 568.