The aerospace industry is subject to significantly stricter requirements than in industry. Particularly compact and lightweight designs are crucial, as every gram of weight and every cubic centimeter of volume saved leads to significant cost advantages. At the same time, exceptionally high reliability is required to ensure the functional chain of complex systems uninterrupted. This is reflected in the long service life required of all components used.

One example of the application of cryogenic technology in space industry is the cooling of fuel tanks in launch vehicles. These are powered by different fuels; liquid fuels must be cooled to extremely low temperatures in order to remain in a liquid state and not evaporate. For future long-term missions to the Moon or Mars, the goal of zero boil-off is becoming increasingly important. In addition, cooling processes based on the reverse Brayton cycle are often used in rockets to achieve cryogenic temperatures. In this process, a gas such as helium is compressed to a higher pressure, then pre-cooled in a heat exchanger and subsequently expanded using an expander, whereby it cools down significantly. This allows cryogenic temperatures to be generated efficiently. Cryogenic cooling by such systems is a highly complex process that demands sophisticated technology and high operational safety.

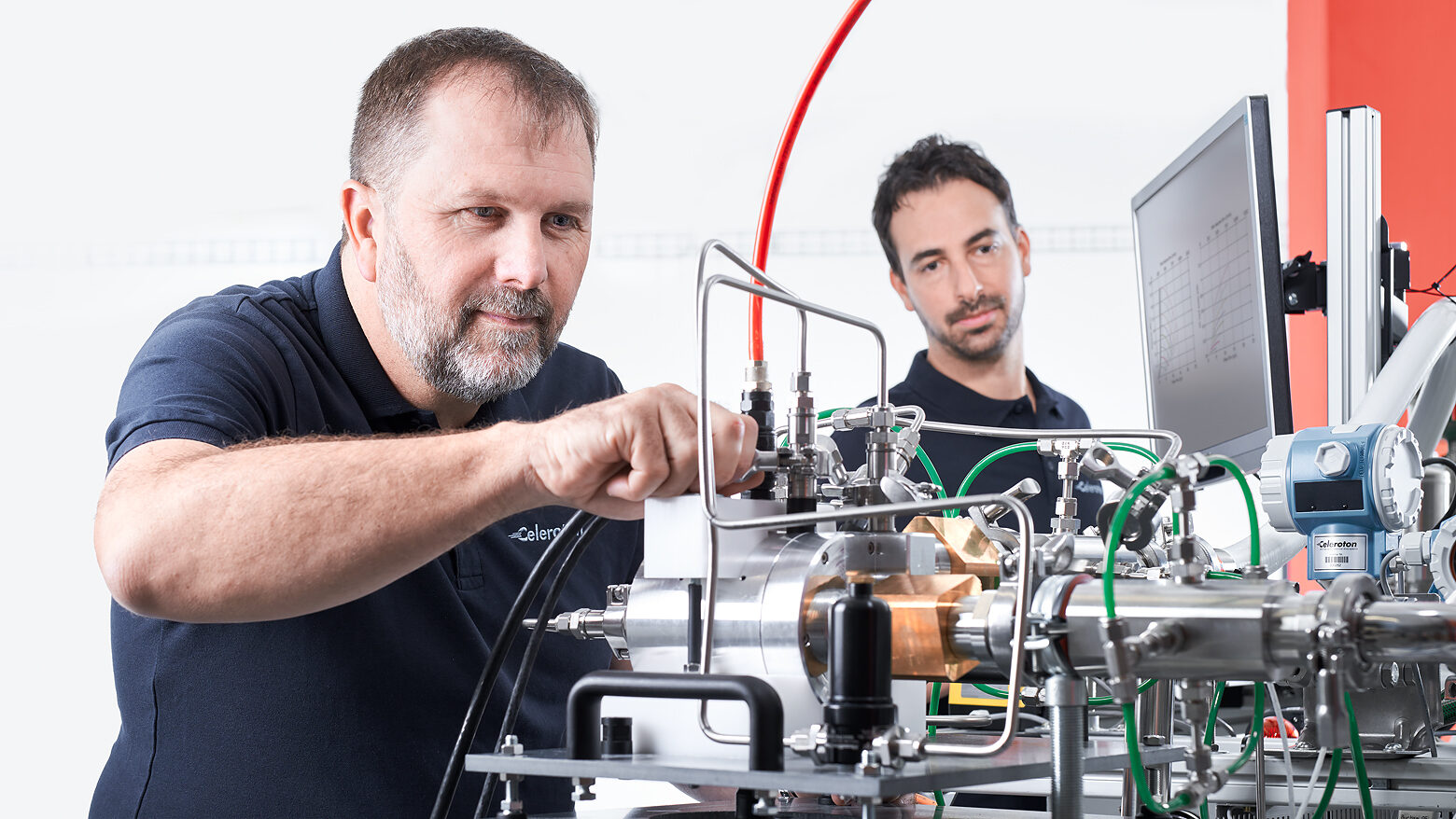

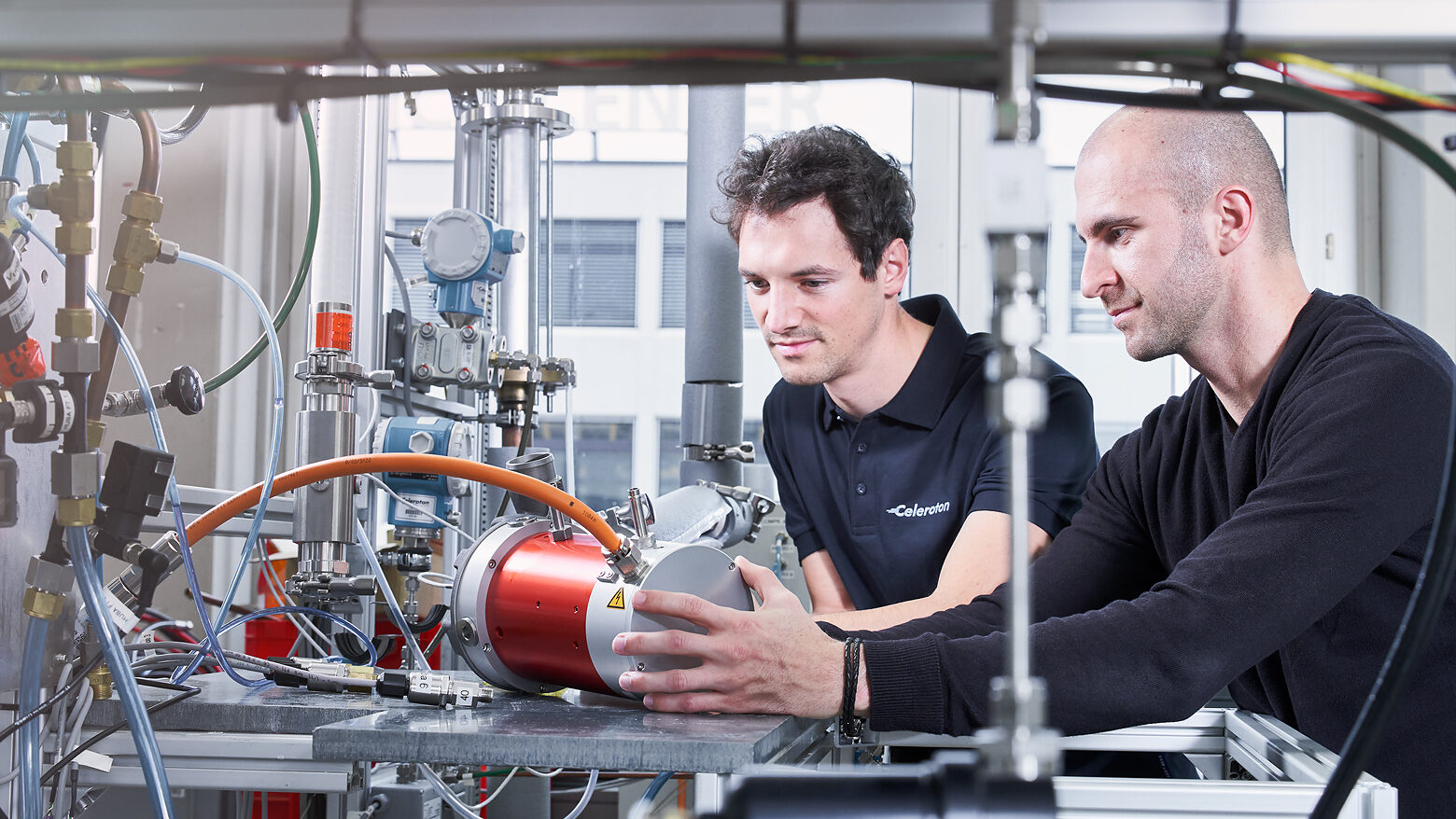

Celeroton’s fluid flow machines meet these requirements perfectly. Both the compressor and the expander are maintenance-free, which significantly increases operational reliability. Thanks to the innovative gas bearing technology, no conventional lubricants are required, as the process gas itself serves as lubricant. This by design prevents contamination. The expanders have been proven at temperatures as low as 20 K. In combination with the appropriate converters from Celeroton, this results in maximum efficiency and flexibility in the control of complex cryogenic processes.

The reverse Brayton cycle can be combined with a cold turbo compressor from Celeroton for further applications to drive a separate cryogenic cycle. This allows decoupling from the main cooling flow and the operation of cryogenic processes with high pressure loss. Since the compressors emit extremely low micro-vibrations, there is no need for complicated mechanical decoupling in sensitive processes, such as in cooling of infrared mirrors.