The aerospace industry has even stricter requirements than conventional industries. The focus is on particularly compact and lightweight construction, as every cubic centimeter saved and every gram of weight reduces costs significantly. At the same time, exceptionally high reliability is required, as maintenance in space is very difficult or even impossible.

A key issue in space travel is thermal management, which is more difficult in space because there is no convection without an atmosphere, only radiation. In the past, heat pipes and mechanically pumped liquid loops were used to remove the heat generated by instruments or people. With Q ∝ T4 for radiation the heat dissipation capacity is increasing with higher temperatures, leading to heat pumps becoming more interesting. This can be seen by increasing research and development activities for space heat pumps. In satellites, or in future space data centers, this serves to efficiently transport heat from its source, e.g., telecom electronics, to the radiator on the outside of the satellite. This concept can also be applied to space stations, for example, to regulate the interior temperature, offering scalable solutions for future Lunar or Martian habitats.

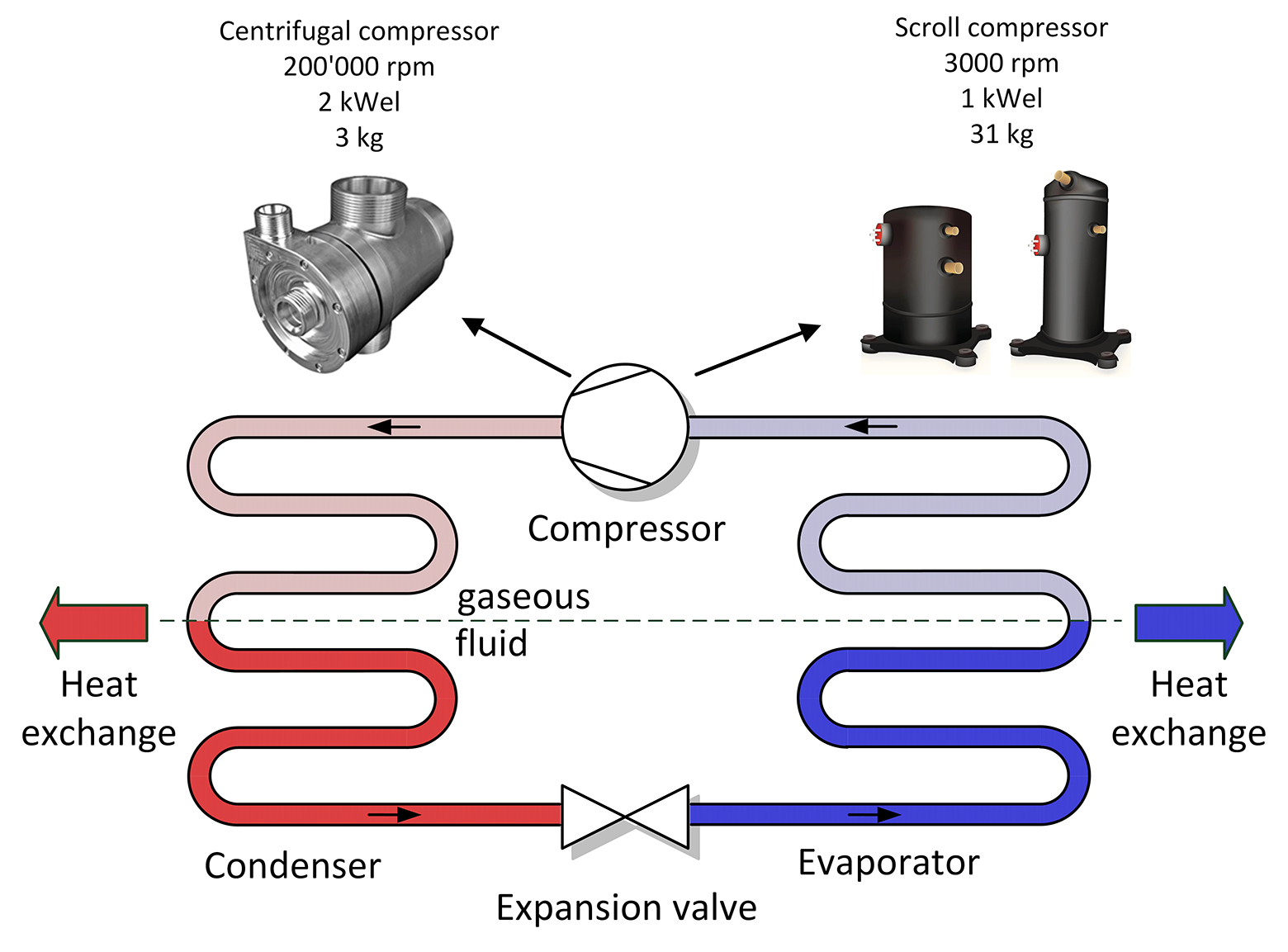

Gas-bearing centrifugal compressors (turbo compressors) are used as the core component of such heat pumps, as they ideally meet the space-specific requirements of low weight, compact design, long service life, low micro-vibration emissions, and oil-free operation. Celeroton’s high-speed compressors provide the optimal solution for this: thanks to gas bearings, the compressors operate completely oil-free, which significantly reduces the risk of refrigerant foaming. In addition, the operating principle of the continuous flow machine translates to operation without pressure pulsations, which further reduces vibration emissions significantly.

The possible applications for heat pumps and thus also for turbo compressors from Celeroton are diverse and are becoming increasingly important in the development of space applications.