Power electronics

Low losses in converter and motor: power electronics demonstrates not only individual responsibility but is a strong team player.

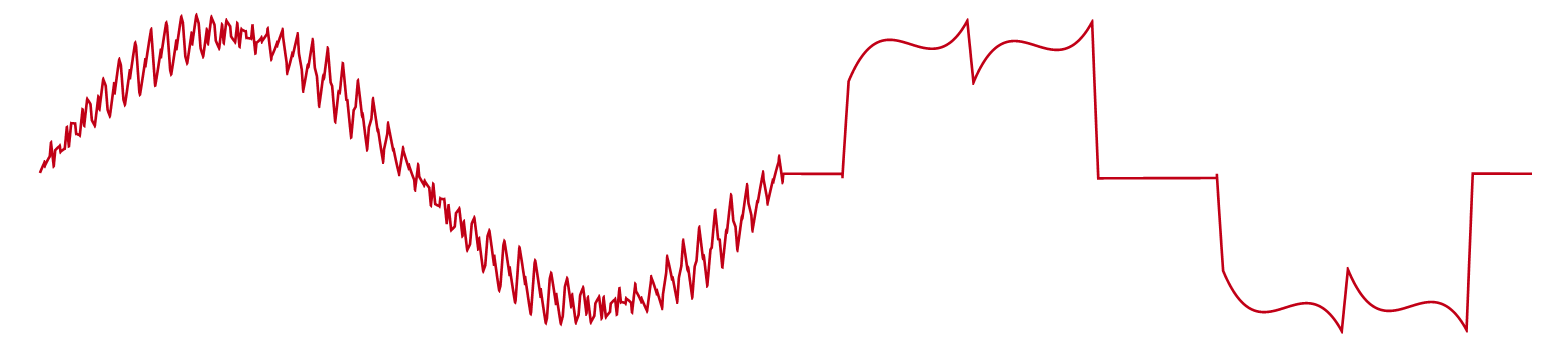

Two-stage voltage source inverters in combination with pulse width modulation (PWM) are the standard for speeds of up to several thousand revolutions per minute (rpm). For applications with speeds of up to several hundred thousand revolutions per minute and/or extreme motor efficiency requirements, other converter topologies and modulation methods may be considered. These include voltage source inverters with an additional DC-DC converter stage, in which the inverter is operated with block commutation, also known as pulse amplitude modulation (PAM). Further advanced topologies and modulation methods are used to integrate the power electronics into a turbo compressor housing. Celeroton’s approach to system design, including motor and converter, enables optimal selection and coordination of the power electronics topology, modulation method and motor topology.

Celeroton’s power electronics and modulation technology are optimized for the electric motors installed in Celeroton turbo compressors, especially for the lowest rotor and converter losses at the highest speeds. This results in the highest power densities in the system.